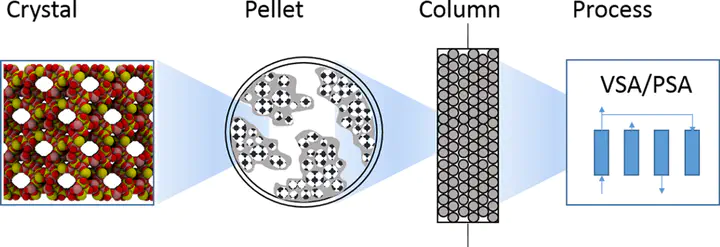

From Crystal to Adsorption Column: Challenges in Multiscale Computational Screening of Materials for Adsorption Separation Processes

Abstract

Multiscale material screening strategies combine molecular simulations and process modeling to identify the best performing adsorbents for a particular application, such as carbon capture. The idea to go from the properties of a single crystal to the prediction of material performance in a real process is both powerful and appealing; however, it is yet to be established how to implement it consistently. In this article, we focus on the challenges associated with the interface between molecular and process levels of description. We explore how predictions of the material performance in the actual process depend on the accuracy of molecular simulations, on the procedures to feed the equilibrium adsorption data into the process simulator, and on the structural characteristics of the pellets, which are not available from molecular simulations and should be treated as optimization parameters. The presented analysis paves the way for more consistent and robust multiscale material screening strategies.