The New Beginnings 2022

I moved to Manchester in January 2020, starting here as the new Head of Department of Chemical Engineering. On the 17th of March, 2020, we had to shut down all the labs and leave the buildings due to the onset of the COVID pandemic. What followed was quite a challenging time for the academic groups and the universities at large. Now, two years later, my research group has relocated to the new building (https://www.mecd.manchester.ac.uk), new group members will be joining us throughout the year and we have plenty of exciting and challenging ideas to work on.

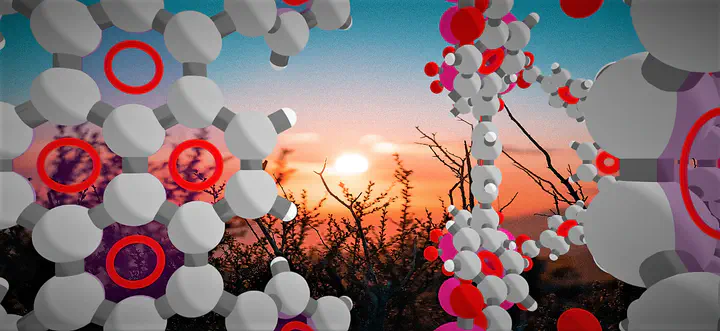

To explain the research vision of the group, let me propose the following imaginary scenario. A chemist envisages a new porous material (let say a MOF, because it is a hot topic at the moment). This material has been already synthesized in the lab, or it can be simply contemplated on a piece of paper. What is this material good for? Sensing? Some adsorption separation processes? Is it flexible? Is it stable with respect to water? Is there a cheap way to synthesize it in industrial quantities? In general, answering these questions requires an extensive and diverse experimental campaign in terms of number of people, experimental techniques and time. However, recently it became possible to answer some of these questions using simulations on a computer.

For example, prediction of adsorption equilibria given structure of a porous material using molecular simulations has become an stablished tool of enquiry. These data can be used at a different level in a process simulation to explore how this material would behave in a real process, such as the PSA cycle for carbon capture. We now have tools and techniques developed in our group to obtain structural features of porous materials, link them to the functional characteristics such as adsorption behaviour, using ML methods, and then, in turn, link process behaviour to adsorption behaviour, also using ML models, bypassing (time consuming) simulations all together.

More recently, we have been leveraging the power of NLP methods to extract useful information on material synthesis from the already published data. Possibly, it will lead to the Digital Assistant system which would advise the experimentalists on the most plausible (cheap, green) conditions for high yield material synthesis. And hence, let’s return to our chemist. She now drops the file with the new (or hypothetical) material structure into a web-based platform, which returns the structural characteristics of the new material (pore sizes, how they are connected), equilibrium adsorption data for target applications, provides a visual guide on the structure and properties of the material, explores its behaviour in a relevant industrial process, and suggests a cheap way to make it.

On the computational side, this is a very challenging endeavour as well, requiring many different types of expertise. And this is what our team is all about: we bring diverse expertise and methods together to advance material informatics to accelerate the deployment of sustainable chemical engineering technologies, while answering fundamental questions, programming a lot, and having a lot of fun in the process. Stay tuned!